What to Consider: Thermal Management for Hydrogen Fuel Cell Electric Vehicle

Commercial vehicles perform a wide range of duties: from conveying packages around towns, to transporting commuters to work, to moving freight across continents. For those vehicles that must travel long distances without stopping, and that must be free from tailpipe CO2 emissions, a fuel cell electric vehicle is a well suited choice. Additionally, the fast refueling time of a hydrogen fuel cell vehicle also reaffirms its suitability for vehicles requiring intensive use.

As in common with a battery electric vehicle, the fuel cell electric vehicle is propelled along the road by providing electricity to its traction motors. However the source of the electricity is the fuel cell, which uses the chemical energy of hydrogen to produce electricity. Two byproducts come from the process of producing the electricity in the fuel cell: water, and heat. If this heat is allowed to build, then the fuel cell becomes less efficient – typically at temperatures above 80°C. It is therefore desirable to have the means to cool the fuel cell to maintain its efficiency.

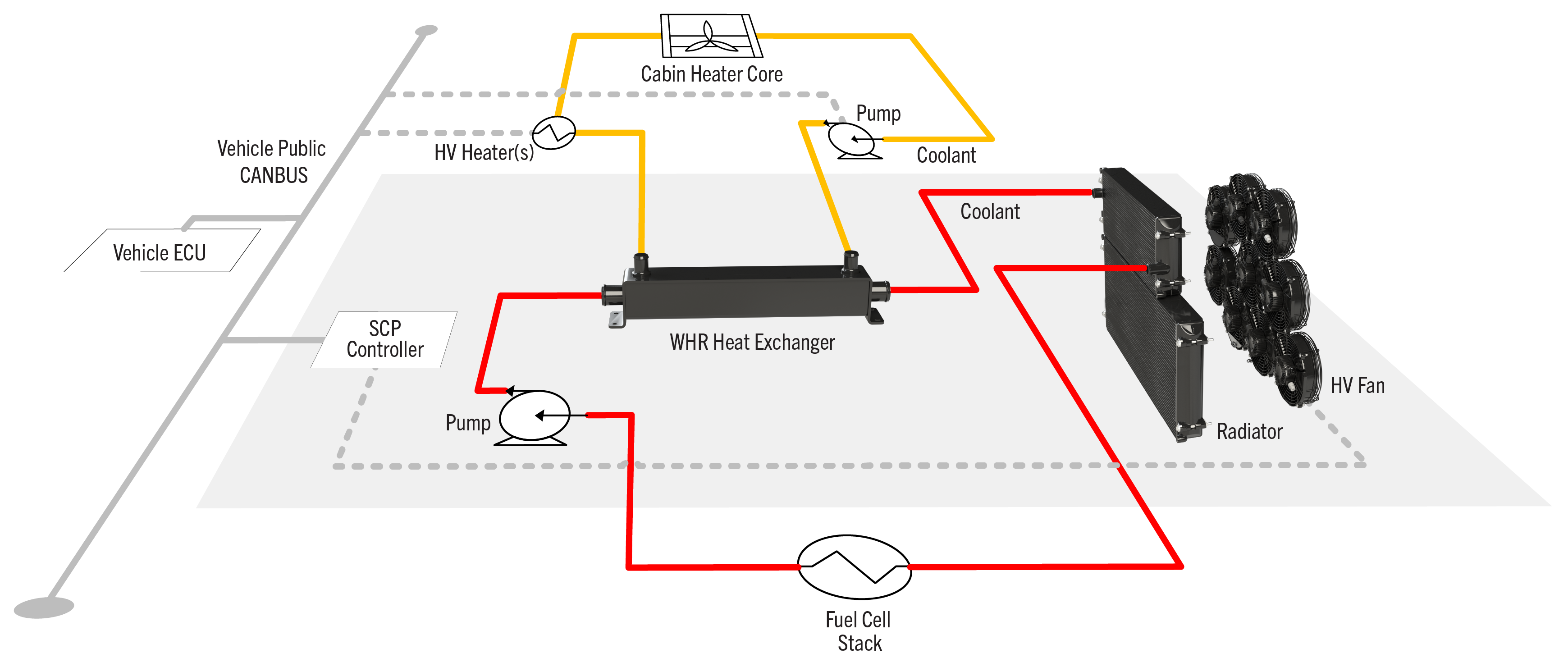

This cooling is accomplished by a Fuel Cell Stack Cooling Package. This passes heat from the fuel cell stack into a coolant, which in turn is pumped into a radiator so that it can be cooled by ambient air. Fans are then used to control the flow of air through the radiator to optimize cooling. From the radiator, the coolant returns to the fuel stack. To improve the vehicle efficiency further, the waste heat from the fuel cell can be recovered through a heat exchanger and passed to a cabin heater, lessening the demand for electricity produced by the fuel cell to be used for cabin heating.

Whilst the basic operating principle of the Fuel Cell Stack Cooling Package is relatively straightforward, a deeper understanding of the requirements of both the Fuel Cell and the vehicle which it propels is needed to ensure the correct component selection and optimum performance and longevity of the Fuel Cell.

At the most elementary level, the Fuel Cell itself will have been designed to have a power output that meets the power demands for the vehicle, and to provide the required energy and longevity to meet the needed duty cycle. This will determine the cooling capacity required, and in turn, will ultimately determine the size of Fuel Cell Stack Cooling Package needed. It is important to note too, that the fuel cell requires that its cooling circuit meets certain conductivity requirements, with any material in contact with the cooling fluid needing to be under that specific requirement. Therefore material selection and processing of the components in the cooling package are critical. When working with Modine, the team will support with product selection, so that the correct Evantage™ Fuel Cell Stack Cooling Package is selected to meet the cooling requirements.

Moreover, in commercial vehicles, duty cycles are often very demanding, with comparatively high lifetimes needed as compared to automotive applications. Here, it is important to select products which are designed to withstand these requirements. Modine’s Evantage™ Fuel Cell Stack Cooling Packages provides this assurance through having been subjected to rigorous testing, by being rated to IP67 for ingress protection, and through the experience of numerous deployments in commercial applications. After selection of the correct Fuel Cell Stack Cooling package, it is important to pick a location that assures airflow to the fans and through the radiators, and also to allow for practical installation of electrical connectors and coolant hoses.

The overall efficiency of the vehicle can also be impacted by the Fuel Cell Stack Cooling Package. This is determined by the power draw of the fans, along with the thermodynamic and fluid dynamic efficiency of the system. Here, Modine’s Evantage™ Fuel Cell Stack Cooling Package is a strong proposition by combining high voltage fans with Modine’s century-plus proven experience with designing radiators for vehicle applications. Extra efficiency can also be brough from the system by integrating a heat exchanger to remove waste heat from the Fuel Cell and deliver it to the cabin heating circuit of the vehicle. Finally, with the Modine-developed firmware included in the master thermal controller, variations in temperature of the fuel cell stack are predicted to within 2°C to 3°C, thereby allowing for a high degree of temperature control to ensure maximum durability and longevity of the fuel cell stack.

In conclusion, the life and performance of a Hydrogen Fuel Cell Electric Vehicle is impacted by the correct thermal management of the waste heat generated. Modine’s Evantage™ Fuel Cell Stack Cooling Packages offer a range of options to do so efficiently and with the optimum performance and reliability that is demanded in a commercial vehicle.