What You Need to Know: Integrating a BTMS into a Vehicle

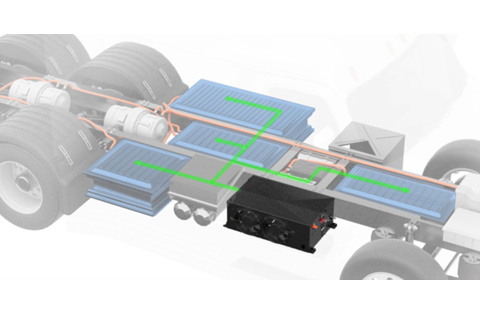

Integrating a Battery Thermal Management System (BTMS) on a Commercial Electric Vehicle (EV) holds the key to enhancing safety, extending range, and optimizing efficiency.

The BTMS constantly communicates with the Battery Management System (BMS) to monitor the battery temperature(s) in real time. The BTMS adjusts the coolant temperature to maintain the batteries within an optimal range as specified by the battery manufacturer. Inside the BTMS, the HV electric heater boosts battery performance and optimizes charging, while the refrigerant loop keeps the batteries cool, ensuring both performance and longevity.

There are three main considerations for successfully integrating a BTMS onto a Commercial EV: Performance Requirements, Space and Weight Considerations, and Software Compatibility.

- Performance Requirements: Understanding how much thermal output each battery in the BTMS’s coolant loop will generate helps determine the performance capabilities the BTMS must meet in order to properly maintain the battery temperature(s). The BTMS must effectively regulate the vehicle’s battery temperatures within the specified range during both vehicle operation and charging.

- Space and Weight Considerations: The capabilities of the BTMS should be balanced with both the physical space constraints and the power draw constraints of the vehicle. Selecting cooling options based on the vehicle’s size and performance requirements enhances the overall vehicle efficiency.

- Software Compatibility: Seamless communication between the BTMS controller and the vehicle’s controller is essential. The desired communication protocols, as well as the preferred procedure for software updates, should be compared against the BTMS’s capabilities to confirm that the vehicle and the BTMS are compatible, simplifying integration and future maintenance.

Successful integration requires close collaboration between the Commercial EV Original Equipment Manufacturer (OEM) and the BTMS manufacturer. This involves selecting a compatible BTMS model that meets performance requirements, space claim, and power draw constraints. Then, customizing the BTMS software to optimize performance and ensure effective communication between the BTMS and vehicle, enhancing overall performance and reliability.

Get in touch with Modine today to work with our engineering team for expert guidance in selecting and customizing the ideal BTMS solution for your application. Our tailored approach leads to peak performance and efficiency, optimizing your commercial EV for the road ahead.